What is AI in Manufacturing?

Hey there! Curious about how artificial intelligence (AI) is transforming the world of manufacturing? You’re in the right place. Let’s dive into some of the common questions people have about this fascinating topic!

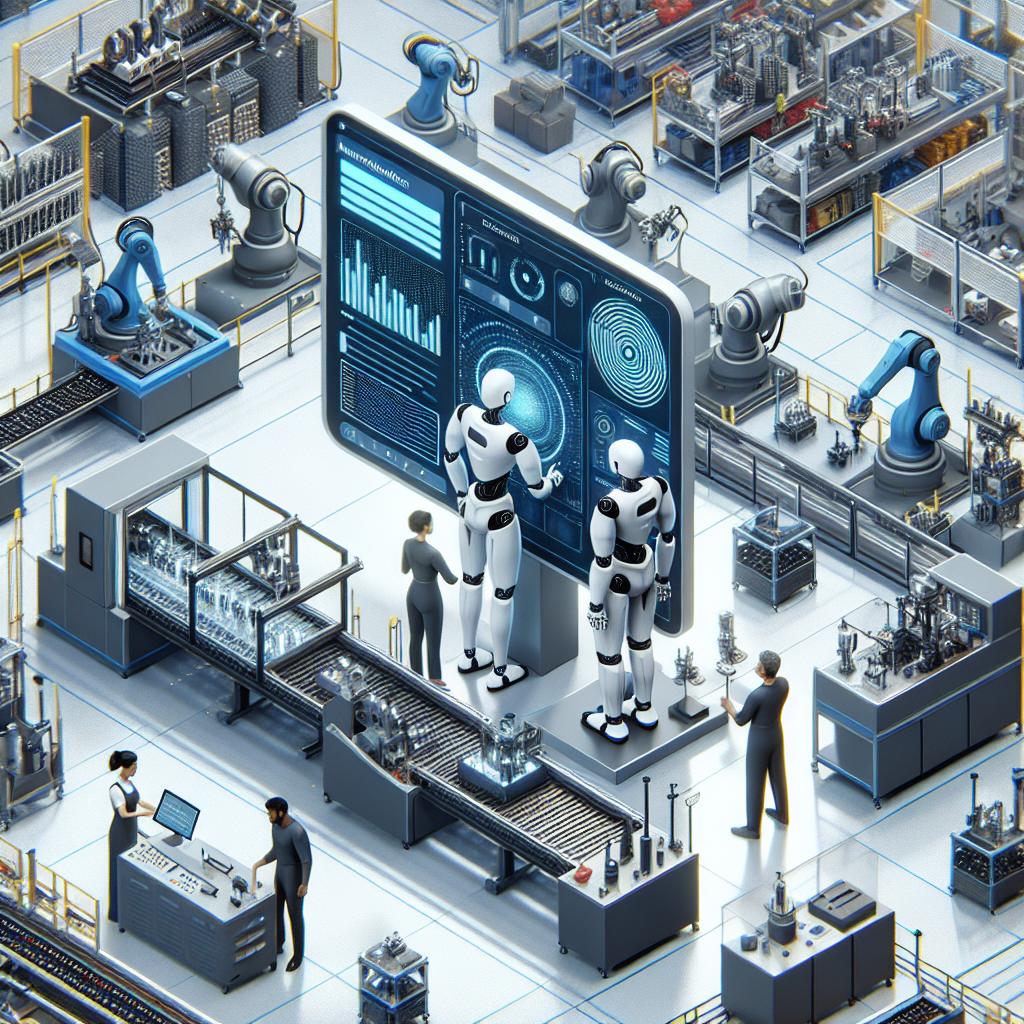

What Exactly is AI in Manufacturing?

AI in manufacturing refers to the application of artificial intelligence technologies to improve and optimize the manufacturing process. This can include things like machine learning, robotics, and predictive analytics. Essentially, it’s all about making machines smarter so they can help us produce goods more efficiently.

How is AI Used in Manufacturing?

- Quality Control: AI systems can inspect products for defects much more quickly and accurately than human eyes can.

- Predictive Maintenance: AI can predict when machinery is likely to fail, allowing for timely maintenance that minimizes downtime.

- Supply Chain Optimization: AI can analyze data to optimize inventory levels, reduce waste, and ensure timely delivery of materials.

- Automation: AI-driven robots can handle repetitive tasks, freeing up humans for more complex activities.

What Are the Benefits of AI in Manufacturing?

- Increased Efficiency: With AI handling repetitive or complex tasks, production processes become faster and more reliable.

- Cost Savings: By optimizing processes and reducing downtime, AI can significantly cut costs.

- Improved Product Quality: AI’s precision helps in detecting defects that human inspections might miss.

- Better Decision Making: AI can analyze vast amounts of data to provide actionable insights, helping manufacturers make informed decisions.

Is AI in Manufacturing Difficult to Implement?

It can be, but it doesn’t have to be overly complicated. The key is to start small with pilot projects to understand how AI can benefit your specific operations. Once you see the value, you can scale up. Partnering with experts in AI can also make the implementation process smoother.

Are There Any Drawbacks to Using AI in Manufacturing?

While AI offers numerous benefits, there are a few challenges to consider:

- Initial Costs: Implementing AI technology can require a significant upfront investment.

- Data Privacy: With increased data collection, ensuring data privacy is crucial.

- Job Displacement: Automation might lead to fewer human jobs in certain areas, though it could also create new opportunities.

What Does the Future Hold for AI in Manufacturing?

The future looks promising! As technology continues to evolve, AI will likely become even more integrated into manufacturing processes. Imagine smart factories where machines communicate with each other to optimize everything from production schedules to energy use! Exciting, right?

So there you have it—a friendly introduction to AI in manufacturing. It’s an innovative field with a lot of potentials. If you’re involved in manufacturing or just fascinated by technology, it’s definitely something worth keeping an eye on!